Button History

Button history from ancient times to the 19th century.

The button as we know it today originated in the Germanic world of the northern part of ancient Europe. Here, people wanted clothing that was easy to remove for active lives, in contrast to the Greek and Roman worlds where the warmer climates encouraged clothing worn loose and fixed lightly with brooches, buckles, or the like. In the medieval period, the Europeans used fewer metallic buttons than people in the Islamic world. Metallic buttons were seen as a luxury whereas other buttons, mostly made of natural materials, were used merely for the practical purpose of opening and closing garments.

After 1400, the Renaissance civilisation saw changes in clothing fashion, and the materials used for making buttons also changed. The different kinds of buttons expanded to those made of precious materials like diamonds, gold, silver, crystal and high-quality shell. Buttons were also embroidered or made with the new technique of mosaic, enamel or beads. Although these buttons were very beautiful, they were expensive and were not commonly used.

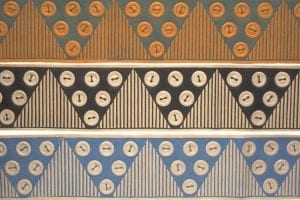

In the 1700s, in keeping with the extravagant Baroque court era, buttons, especially men's buttons, entered their golden age as a handcraft and many guilds of button craftsmen were established. In the Rococo age, buttons were seen as an elegant status symbols, and many sophisticated examples were made with intaglio or inlay pearl-shells, or decorated with painted ivory. These buttons included those made with micro mosaic techniques or with superb embroidery skills.

In contrast to the style of the Rococo age, practical metal button techniques were developed in England, particularly in Birmingham, mainly for use in the rapidly expanding market of military uniforms. The compressing technique contributed to the making of buttons from other types of natural materials buttons at this time. In addition, new materials like Wedgwood or Sevres ceramics, cut steel, and Strass (a form of diamond imitation) were used for button making.

In the 1800s, changes in the daily social lives of the bourgeoisie followed the political changes in Europe and the Industrial Revolution. The clothing of the bourgeoisie became more practical, and the buttons were made of materials such as cloth, fiber, passementerie, or metals. The most popular color was black. After the funeral of her husband in 1861, Queen Victoria loved to wear black, and this fashion became very popular in England and also in other European countries. Black buttons were made from many different materials including, onyx, jet, ebony, Japanese lacquer and mostly pressed black glass.

Victorian people liked buttons with lithographs featuring a portrait or romantic motifs such as hearts, angels and cupids. Children's scenes from the books of Kate Greenaway, a popular illustrator of the period, were also depicted on buttons. Such figurative buttons were referred to as "picture buttons". After 1840 or so, glass buttons were widely produced in Germany and Czechoslovakia. In addition to souvenir buttons, exotic materials such as ivory, jade,coral, tortoise-shell and high quality pearl-shell were used for button making throughout the century. In Japan, the Satsuma buttons were exported for foreign currency earnings.

During war periods, metals were no longer readily available for button manufacture, and alternative materials were sought. In the years of peace, the button makers searched for ways to imitate the more expensive and precious materials for their buttons. And thus began the era of the modern button production. Between 1840 and the 1930s, buttons made from South American tagua nuts called corozo or "vegetable ivory", were mass-produced in factories for use mainly in men's clothing. The tagua nuts' role in button making preceded that of the plastic button.

During the last decade of the 1800s, the so-called "Gay 90s", the fashion for ladies included big heavy-coat buttons decorated with engraved metal frames and centered with large showy glass. These buttons were exported , especially from France and Germany, to the new industrialized and affluent country, America.

Buttons in the 20th century - Century of plastic buttons.

Casein

Casein, a milk protein , was first mixed with formaldehyde in 1890s in Germany to form a plastic know as galalith. Galalith is a warm and fine-textured substance with many possibilities as a material for buttons. It was especially loved by northern Italian button craftsmen and used for making buttons, particularly sample buttons for the French market. This material was mainly produced and utilized in Germany, France and America for buckles and other accessories.

Celluloid

Celluloid appeared in the 1870s, initially as an alternative to ivory for making billiard balls. It was not a perfect synthetic substance, a major drawback being its low resistance to heat. Nevertheless, celluloid became popular for making buttons because it took colors well and could be manufactured to imitate the texture of various materials including natural materials. It was widely used in button manufacture until the 1950s.

Bakelite

Invented in 1907 by a Belgian, Leo Baekeland, bakelite is referred to as the "jewel among plastic materials". It is considered to be the first "perfect" synthetic material because of its strength, beauty and brightness. It has been employed in the manufacture of a host of everyday items including automobiles, radios, telephones, stationery, tableware, and cosmetics containers etc. Initially, it could only be made in dark colors, but the 1930s saw the development of light-colored bakelite. This material was creatively utilized in jewelry, accessories, buckles and buttons, and was seen as a happy combination with the Art Deco taste of that period. The transparent bakelite, called "apple juice color", which discolored in time, has today become a sought after collectors' item.

Lucite

An acrylic plastic, called lucite, was developed during the 2nd World War as a material for airplane parts because of its strength and transparency. These properties also made lucite a popular material for button and accessories manufacture, and it was particularly popular in the 1940s and 1950s.

Special resins

Cellulose acetate, a kind of special resin originating from petrochemical products, was used in the 1950s for making various fancy buttons because it readily took interesting colors and textures. It accurately reflected hand-made tastes. However, they showed low heat resistance and were difficult to clean.